1. The corn kernel processing production line provided by Donglong Refrigeration is high-grade, easy to use, beautiful reliable.

2. The corn kernel processing production line adopts the latest processing technology, the production line equipment is complete complete, the processing technology is advanced. The processed corn kernels are 100% monomer, good quality, free of impurities, clear size specifications, the corn kernels look good in color sell well after freezing. .

3. Donglong Refrigeration has 20 years of experience in production line design, manufacture, installation commissioning. The corn kernel production line has very mature technology, high operating reliability, greatly reduced failures during operation. Corn kernels are of good quality after processing.

3. Material used in the production line: high quality SUS304 stainless steel material. The equipment processing adopts laser processing technology, the equipment is well-manufactured.

5. Design manufacture the production line according to the export food hygiene safety requirements (HACCP).

6. The production line has complete equipment configuration advanced technology. After 3 steps of removing impurities + finished product classification, the quality of frozen products can satisfy all customers.

7. The whole production process is automatic conveying processing. The degree of automation is high, the number of workers is small, the quality after processing is good.

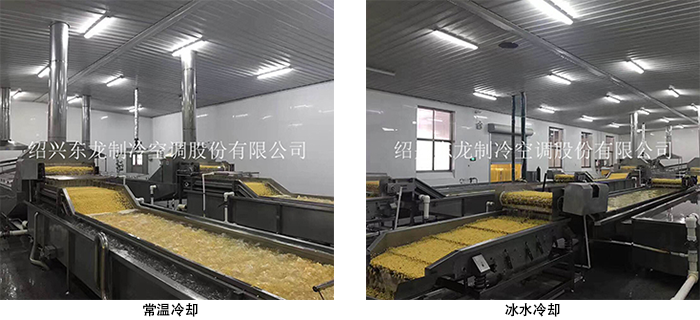

Corn kernel quick-freezing processing technology: corn cob peeling-threshing-one-step winnowing to remove impurities-two rollers to remove impurities-three comprehensive cleaning-washing-blanching-room temperature cooling-ice water cooling-draining-quick freezing-size classification-packaging

Production line specifications: 2-6T/h, customized according to customer needs.

Quick freezing