I. Overview

SLD series of new high-efficiency fluidized quick-freezing machine is a new generation of quick-freezing device newly developed by our company by absorbing the advanced technology at home abroad, taking advantage of the advantages avoiding the shortcomings, integrating the strengths of each family. The machine incorporates new quick-freezing technology new design concepts, uses a number of fluidized freezing technologies.

SLD fluidized quick-freezing machine is the best quick-freezing equipment to realize the fluidized monomer freezing of fruit vegetable foods some seafood. The frozen product is on the stainless steel conveyor belt, the cold air blows upward under the mesh belt. The frozen product is blown by the strong wind. The frozen product is frozen in a suspended state. The cooling is completed in a short time, the surface layer is frozen, the deep layer is frozen, so as to obtain a better monomer Frozen goods.

2. Product features

SLD fluidized quick-freezing machine is designed manufactured according to HACCP requirements, using laser processing technology. Comply with international food (safety) hygiene standards. has the following characteristics:

1. Model structure

Using mature European models with reasonable structure, it can achieve the ideal quick-freezing effect for different product shapes sizes.

2. High efficiency fan

It adopts a high-powered, powerful high-performance fan with large air volume fast freezing speed, which can blow up large particles of frozen products realize fluidized freezing.

3. Adopt reliable two-stage mesh belt operation mode

A. Advanced freezing technology to improve the individual freezing quality of frozen products.

B. Reduce the possibility of material leakage material clamping during mesh belt operation.

C. Reduce the mechanical operation failure of the mesh belt.

4. Evaporator with large cooling capacity

A. Aluminum alloy material, efficient cooling long service life

B. Large duralumin alloy fins, the fins are thickened to 0.5mm, the high-pressure water washing will cause the phenomenon of falling

C. Design with a large distance between the air inlet surface, which is easy to form frost

D. Large duralumin alloy fins can defrost quickly cleanly, facilitate cleaning, reduce the growth of bacteria.

5. Mesh belt vibration chaining device

The use of advanced high-frequency vibration chaining device, small amplitude, can reduce the damage to the mesh belt, at the same time assist the fan with strong wind to make the freezing the mesh belt easy to adhere (price of the fruit quick-freezing production line).

6. Mesh belt cleaning

The mesh belt cleaning drying device is installed at the feed inlet, which can clean the debris frost layer on the mesh belt.

7. High-performance insulation library board

It adopts double-sided stainless steel inner polyurethane board, which is formed by imported production line once, with good heat preservation effect beautiful appearance (evaporative condenser company).

8. Scientific reasonable structure

It is easy to produce sanitary dead corners in the freezing warehouse, the maintenance cleaning equipment are convenient.

model performance | SLD-1000 | SLD-2000 | SLD-3000 | SLD-4000 | SLD-5000 |

Freezing capacity(kg/h) | 1000 | 2000 | 3000 | 4000 | 5000 |

Freezing timemin | 5-30minSteplessly adjustable | ||||

Feed temperature | ≤15℃ | ||||

Discharge center temperature | -18℃以下 | ||||

Cooling when freezing | -35℃±2℃ | ||||

Refrigerant | Ammonia Freon | ||||

Cold consumptionkw(35℃/-40℃) | 186 | 325 | 510 | 680 | 840 |

Installed powerkw | 60 | 80 | 105 | 120 | 140 |

Freeze library sizem(Length×width×height) | 8×4.7×3.6 | 11×4.7×3.6 | 13×4.7×3.6 | 15×4.7×3.9 | 18×4.7×3.9 |

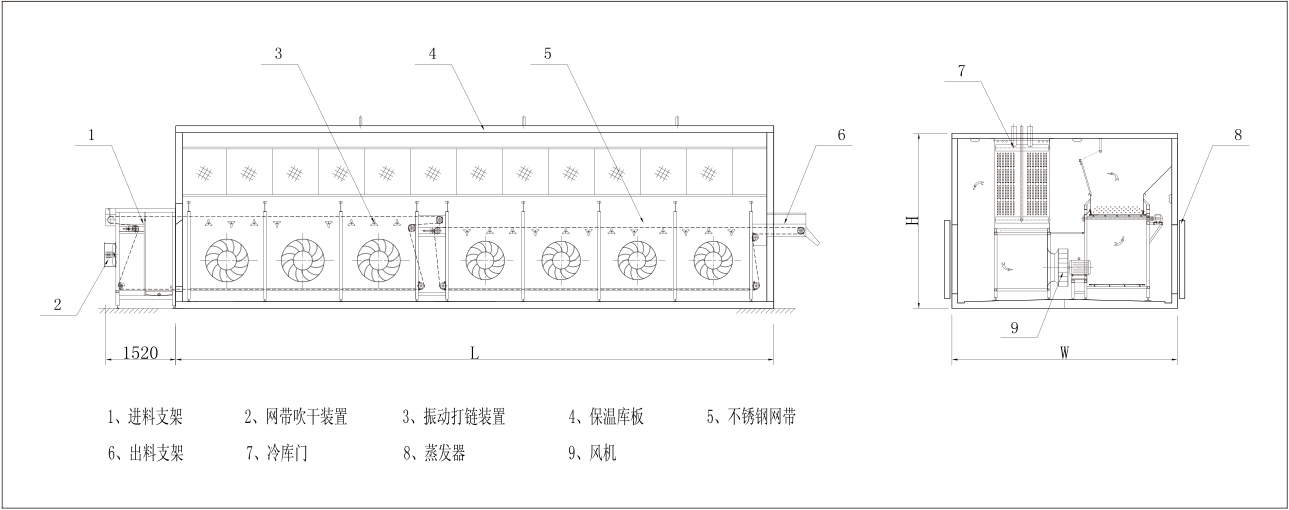

Schematic diagram of fluidized quick-freezer structure